Click The Button On The Right To Learn More About The Company.

Whatsapp

Whatsapp

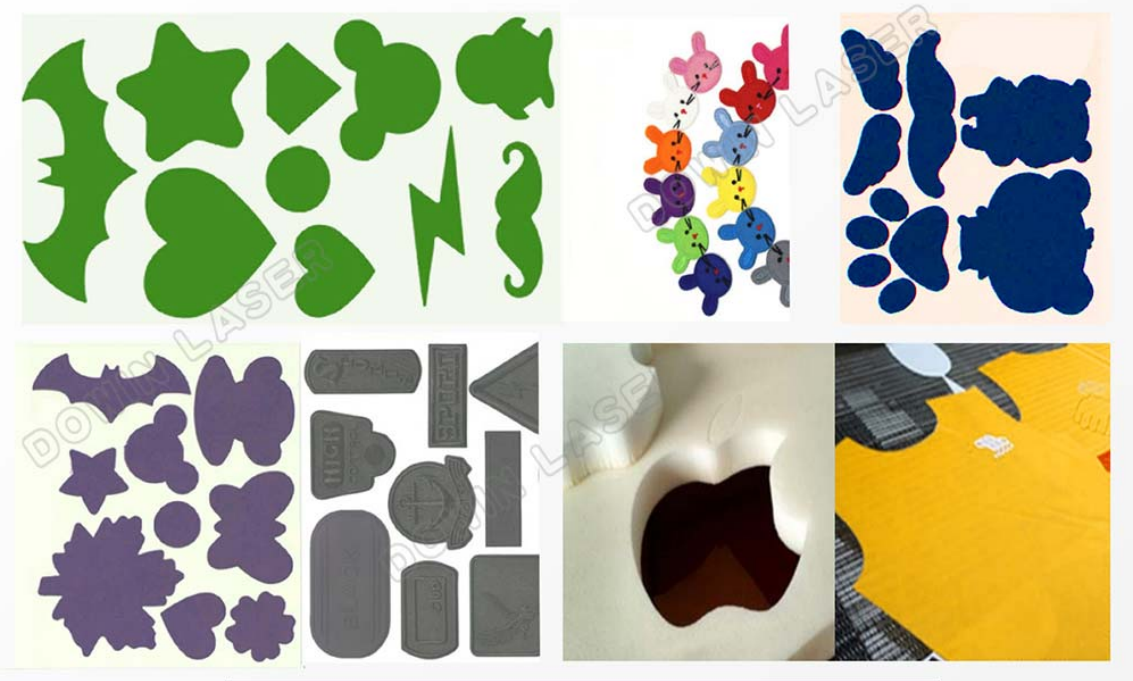

As we know Co2 laser cutters use the strong laser beam to engrave and cut the materials, it could cut all burned materials like fabric, textile, leather, wool cloth with soft nap , PU , genuine leather , organic glass, PVC, paper , wood , bamboo rubber , resin and other non-metal.

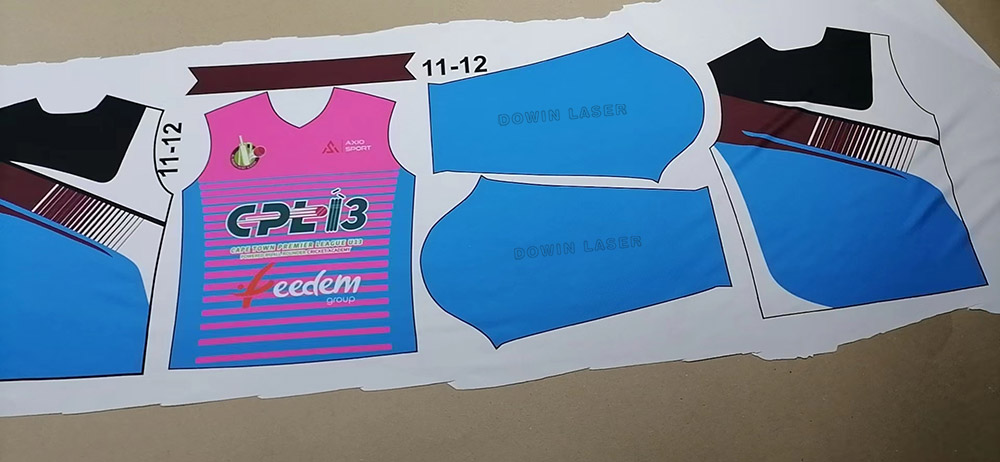

This vision laser cutter is the Co2 laser cutter combined with the advanced large vision software system of Dowin laser.It can automatically recognize the contour of the printed or embroidered fabrics, leather, and other flexible materials and then cut with super-high accuracy and efficiency.This fabric laser cutting machine comes with Auto feeding belt , mainly used for soft materials cutting,combine with top Camera which could scan and recognize the outline and cut according to the outlines. That’s why it could cut the printed fabric.

DOWIN fabric laser cutter DW-1812 with top Camera is Widely used in the industries of fabric,sportswear clothing, labels, garment, footwear, cloth toy, computerized embroidery ,Swimwear,dance wear ,printed clothing,home textiles,footwear,lace,hand bags,gloves,sofas,luggage,car seats,leather products,plush fabric toys,paper products, advertising flags, shoes,toys, non woven art craft...

Laser machines can cut and engrave fabrics better than any other mechanical tool, With synthetic textiles, the heat of the laser seals the edges and prevents fraying. They ensure perfect results harming it in any way. Thus, it is the perfect choice for textile industries, tailors, and designers.

|

Comparison of Fabric Processing Machines |

||

|

Factors |

CO2 Laser Cutting |

Knife Cutting |

|

Cutting Speed |

Fast |

Slow |

|

Cutting Edge Quality |

Smooth |

Frayed |

|

Constant Cutting Quality |

Constant |

Decreasing |

|

Dust Free |

No Dust |

Conditional |

|

Edge Sealing |

Well Sealed |

None |

|

Flexibility |

High |

High |

|

Material Distortion |

None |

Yes |

|

Multi-layer Cutting |

Conditional |

Yes |

|

Tool Wear |

Zero Wear |

Worn to Change |

|

Maintenance |

Low |

High |

|

Environmental Requirements |

No Special Requirements |

Enclosure Needed |

|

Model |

DW-1610/1812/1825CCD |

|

Processing area |

1600*1000mm/1800*1200mm/2500*1800mm |

|

auto feed cutting table |

yes |

|

cutting Speed |

0-18000mm/min |

|

Camera |

Canon |

|

laser tube power |

130W/150W |

|

Laser wave length |

10.6um |

|

Resolution ratio |

0.025mm |

|

Minimum shaping character |

Chinese character 2mm/ letter 1mm |

|

Resetting positioning accuracy |

±0.01mm |

|

Voltage |

Ac220v±10%,50HZ/60HZ |

|

Operating Temperature/humidity |

0℃-45℃/5%-95% |

|

Graphic Format Supported |

BMP,HPGL (PLT), DXF, G-CODE, DST,AutoCAD, CorelDraw, CAD CAM, AI, Photoshop |

|

software supported |

Coreldraw,AutoCAD,Photoshop.llustrator etc |

|

lens |

reflect lens(3pcs)+import focus lens(1pcs) |

|

Driver Type |

Leadshine servo motor |

|

cooling sytem |

S&A CW-5200 |

|

software |

TROCEN |

|

Operate System |

Win98/Win2000/WinXP/Win 7/vista |

|

interface |

LCD screen with USB interface |

|

pass through doors |

Allow to cut extremely long materials |

|

Free Assistant equipment |

exhaust-fan,air pump,industry chiller CW5200 |

|

Optional |

One head/Dual heads same steps/Dual X rails |

|

Dimension /wooden packing size |

238*220*115cm/250*230*130cm |

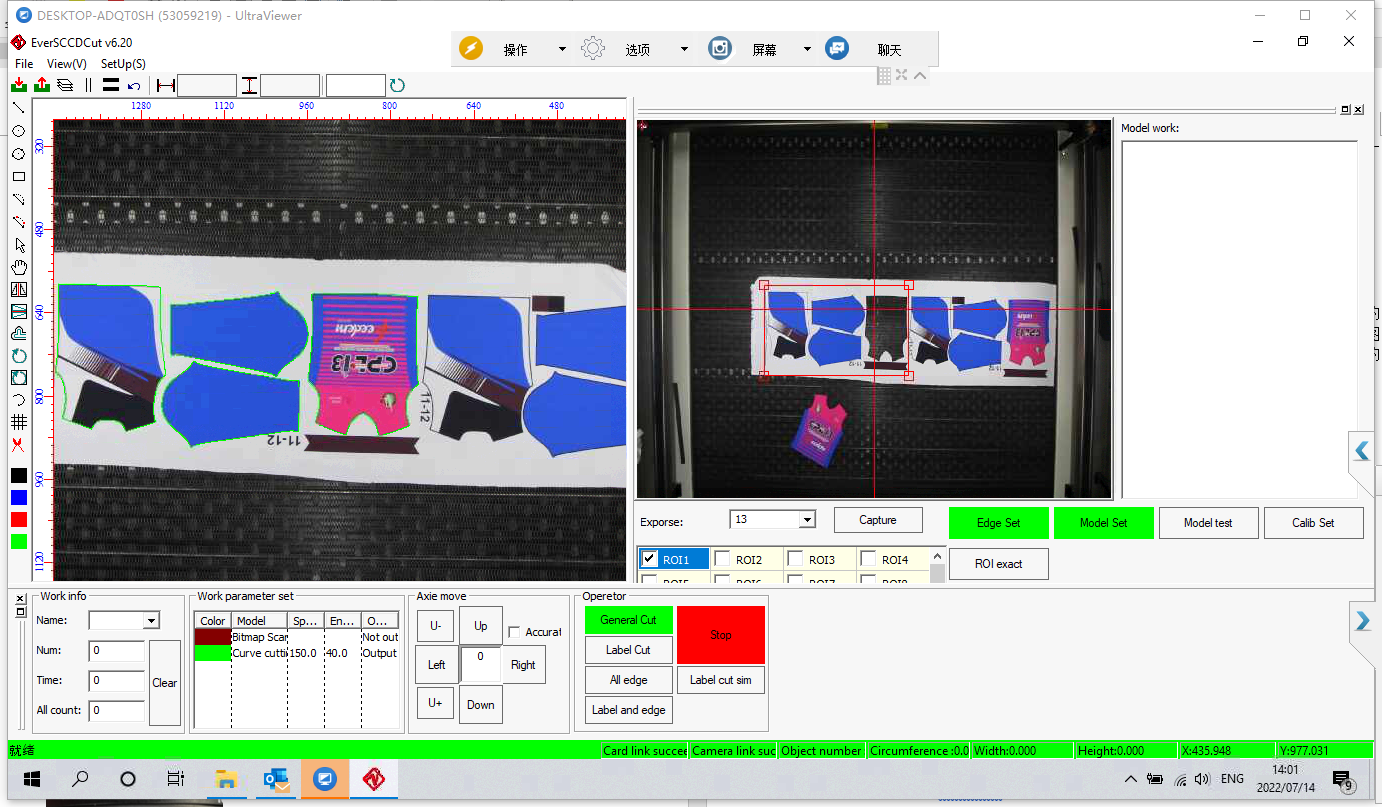

The software detects the contour according to the big color difference between the printing outline and materials background. Do not have to use the original patterns or files.it is a fully automatic process without manual intervention. Detection of printed fabrics directly from rolls, without any preparation.And because the camera takes photos after the fabric is feeding to the cutting area, the precision will be very high.

Camera is mounted on the top of the laser cutting machine, After the material is fed to the laser cutting table, the camera takes a photo of the printed pattern at once in the entire work area at one time. The software automatically creates a file according to the shape and size of the pattern, and then the laser heads cut precisely along the outline of the pattern. It only takes about 10 seconds to take pictures and create files.

Step 1.Prepare any printed materials.

Step 2.camera picks up the outline and tell software where to cut.

Step 3.cutting and collecting pieces.

Click The Button On The Right To Learn More About The Company.

Send Your Inquiry Now!

1.What is your main processing requirement? Laser cutting or laser engraving (marking) ?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. Your company name, website, Email, Tel (WhatsApp…)?Are you reseller or need it for your own business?

5. How do you want to ship it , by sea or by express , whether do you have your own forwarder?