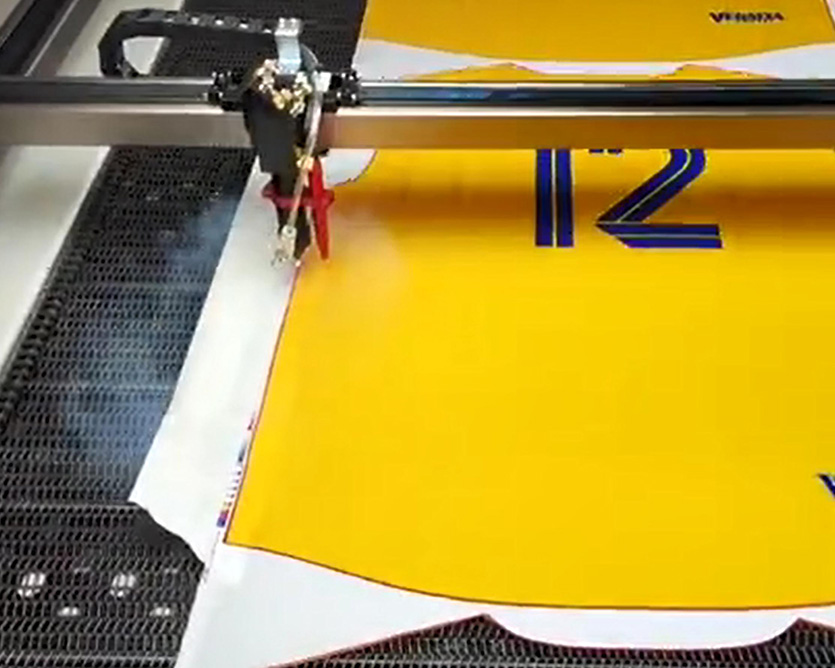

Video introduction

Tech Specifications

|

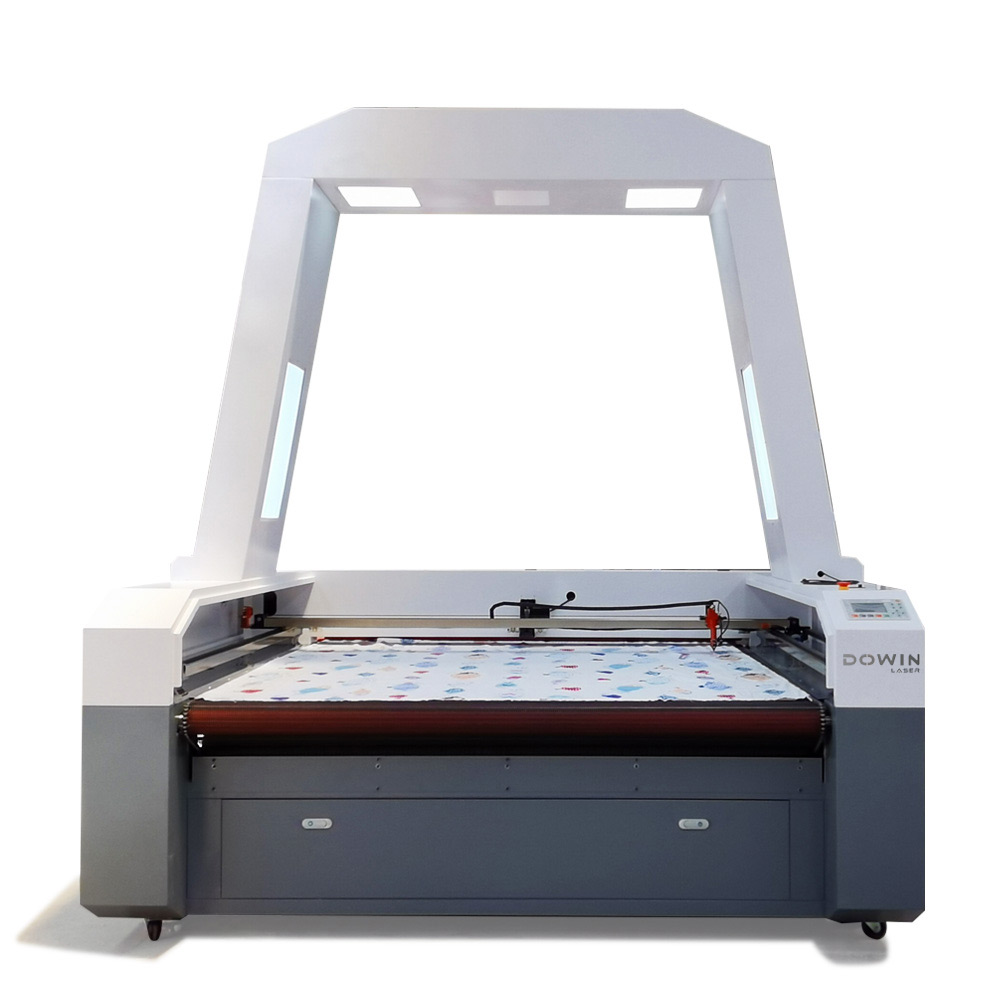

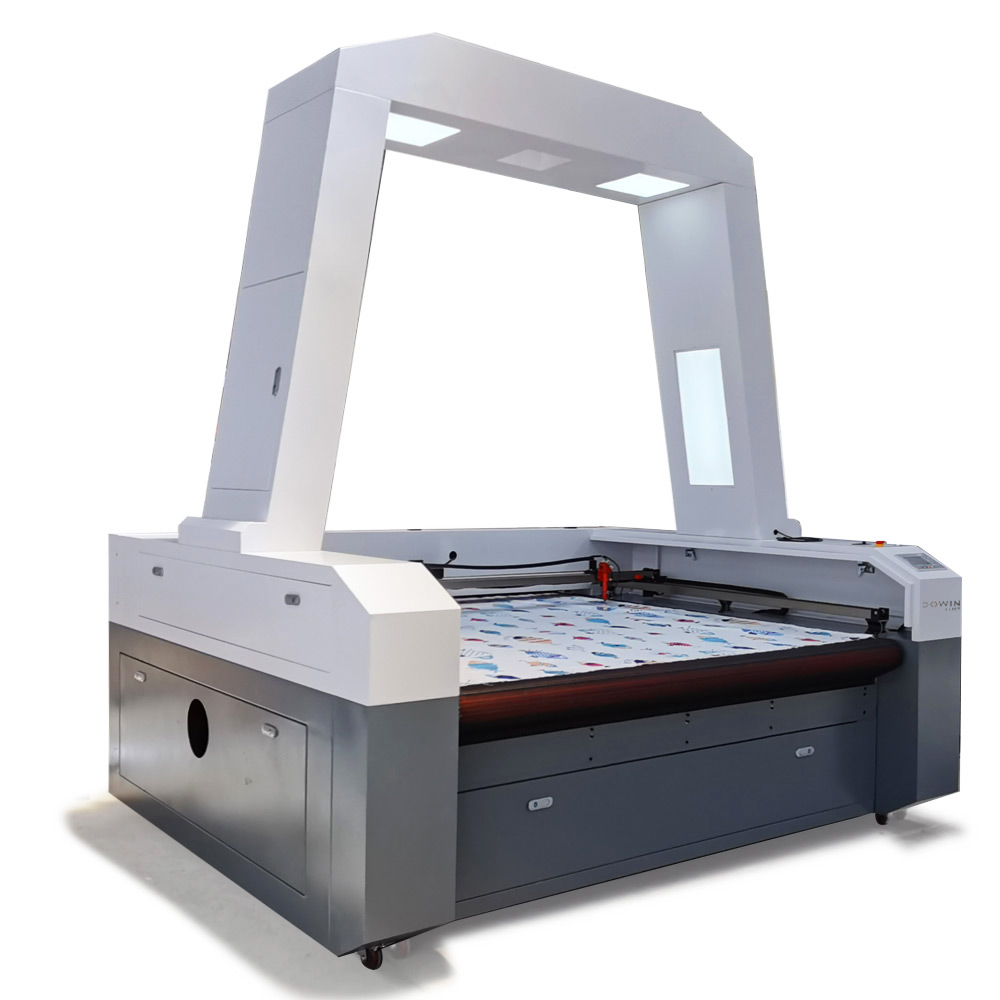

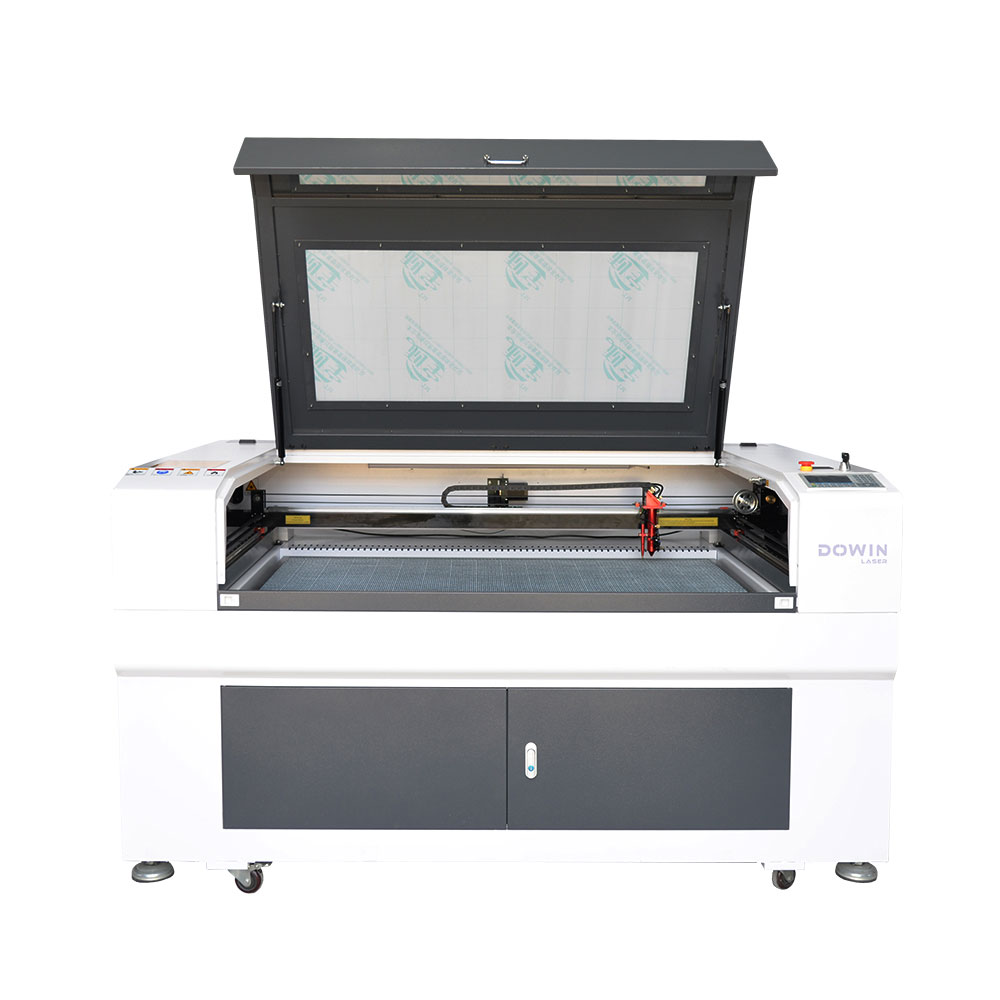

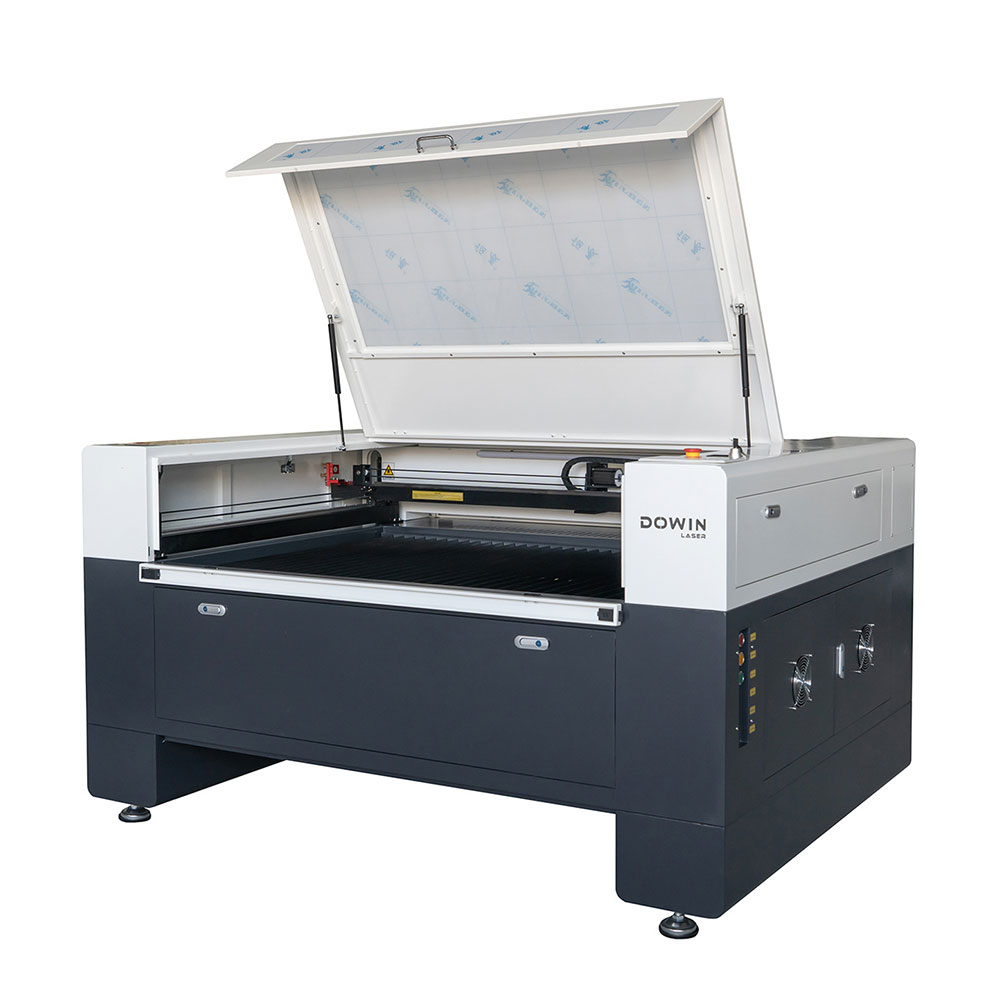

Model |

DW-1814Camera (DW1610/1812Camera) |

|

Processing area |

1600*1000mm/1800*1200mm/1800*1400mm |

|

auto feed cutting table |

yes |

|

cutting Speed |

0-18000mm/min |

|

Camera |

Canon |

|

laser tube power |

80W/100W/130W |

|

Laser wave length |

10.6um |

|

Resolution ratio |

0.025mm |

|

Minimum shaping character |

Chinese character 2mm/ letter 1mm |

|

Resetting positioning accuracy |

±0.01mm |

|

Voltage |

Ac220v±10%,50HZ/60HZ |

|

Operating Temperature |

0℃-45℃ |

|

Operating humidity |

5%-95% |

|

Graphic Format Supported |

BMP,HPGL (PLT), DXF, G-CODE, DST,AutoCAD, CorelDraw, CAD CAM, AI, Photoshop |

|

software supported |

Coreldraw,AutoCAD,Photoshop.llustrator etc |

|

lens |

reflect lens(3pcs)+import focus lens(1pcs) |

|

guide Rail |

high quality mould rails |

|

Driver Type |

leadshine stepmotor |

|

cooling sytem |

S&A CW-5200 |

|

software |

TROCEN |

|

Opearate System |

Win98/Win2000/WinXP/Win 7/vista |

|

interface |

LCD screen with USB interface |

|

pass through doors |

Allow to cut extremely long materials |

|

Free Assistant equipment |

exhaust-fan,air pump,industry chiller CW5200 |

|

Optional |

One head/Dual heads same steps/Dual X rails |

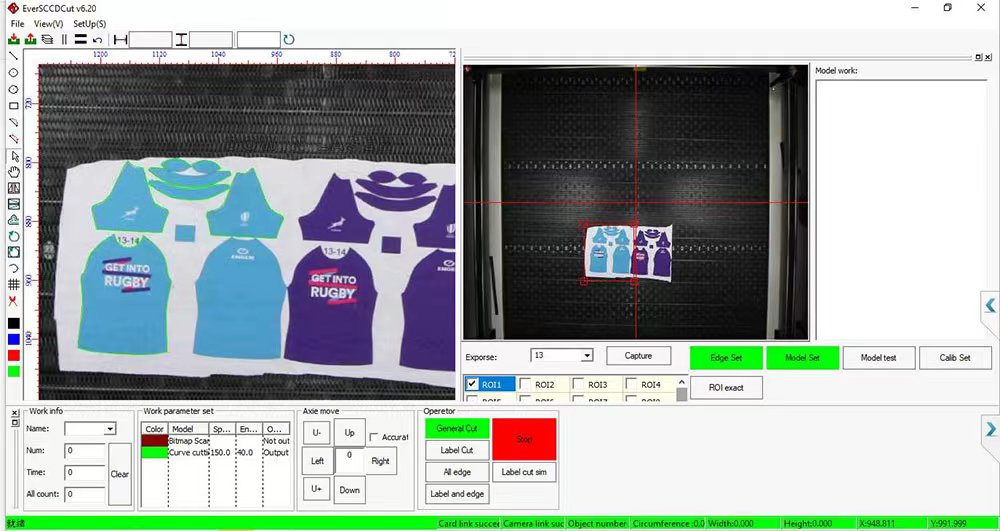

Canon EOS camera

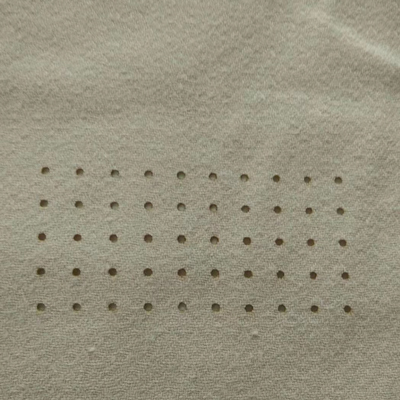

The 2,400-megapixel Canon EOS camera can more clearly map the details of the fabric pattern, ensuring that the cutting position and cutting process can be completed more accurately.

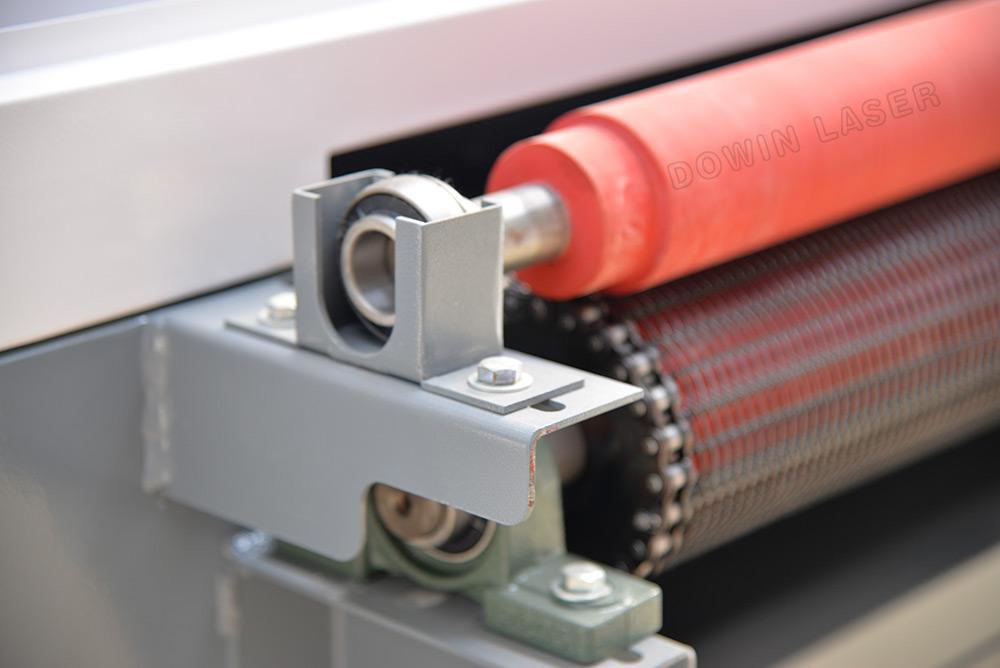

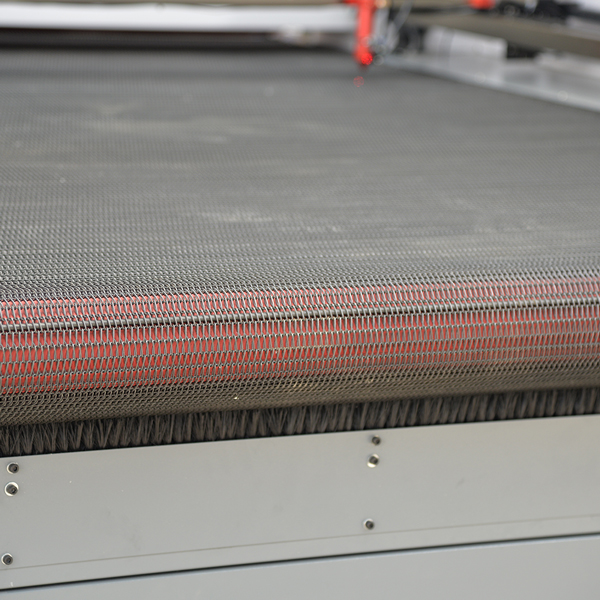

Automatic feeding platform

The use of the chain conveyor belt can save manual operation and further ensure the safety of the operation, while improving the efficiency of the machine work. At the same time, the automatic conveying of the cloth can also reduce the error as much as possible and avoid waste.

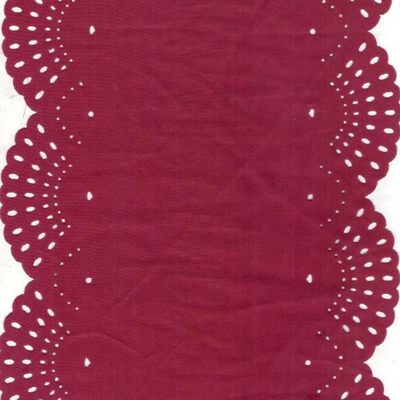

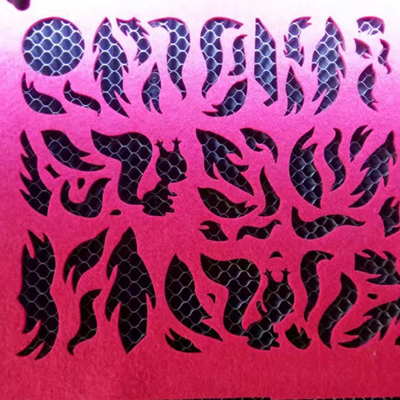

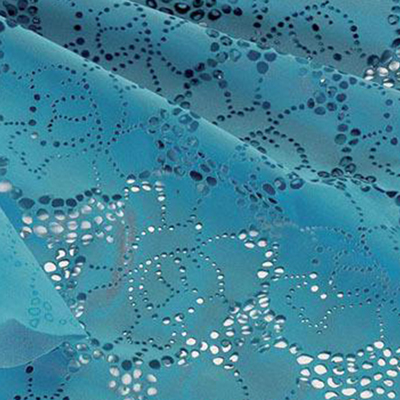

To provide you with a one-stop fabric laser cutting solution