Whatsapp

Whatsapp

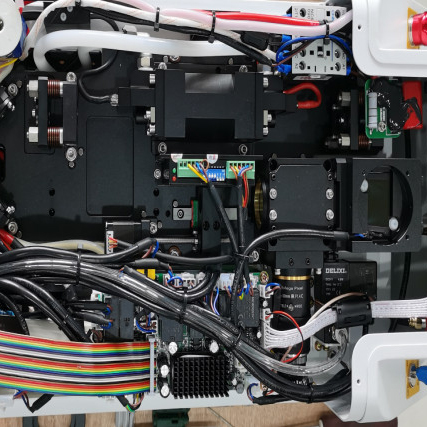

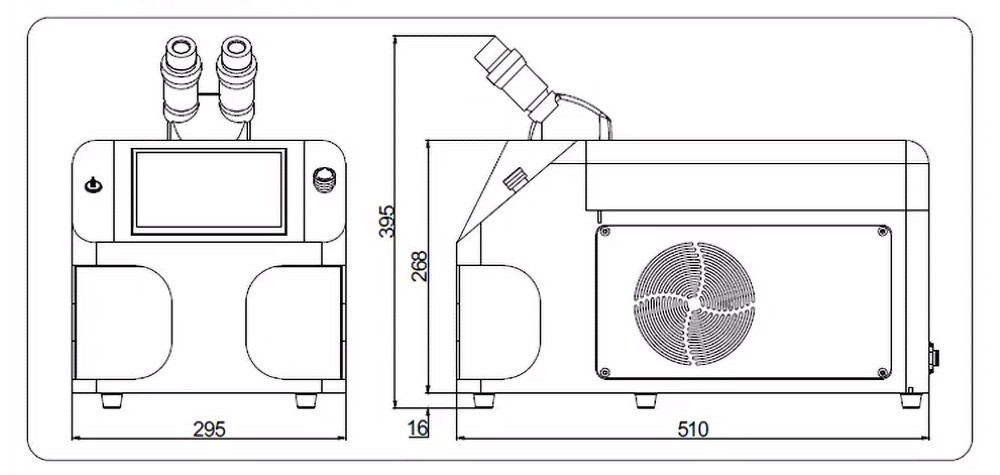

The mini laser welding machine is composed of laser power supply, optical system and cooling system. The closed laser optical path design can effectively prevent the leakage of laser radiation, which is safer. The welding process is achieved by applying high-energy pulsed laser. Finer laser welding spots can perfectly weld jewelry and precision components.

| Model | DW-WA100W |

| Laser Power | 100W |

| Wavelength | 1064nm |

| Gavityng speed | Ceramic cavity |

| Crystal | 7*110 |

| Pulse width | 0.1-10ms |

| Max single pulse energy | 100J |

| Pulse frequency | 1-15HZ |

| Adjusting scope of spot | -3-+3mm |

| Cooling system | Water cooling |

| Total power consumption | 2KW |

| Power supply | AC220±10%&50Hz |

| Monitoring system | CCD and 10x microscope |

High Efficiency: The high-energy laser beam of the air-cooled laser welding machine can quickly melt the material and achieve efficient processing.

High Precision: The precise control of the optical system and the processing head can achieve precise welding and processing, meeting the welding needs of delicate items such as jewelry.

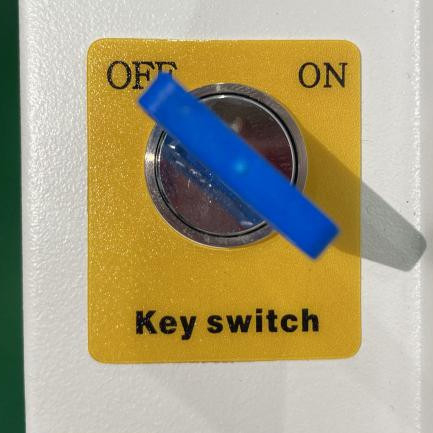

Easy to Operate: The equipment is simple to operate and easy to use, suitable for workers of all operating levels.

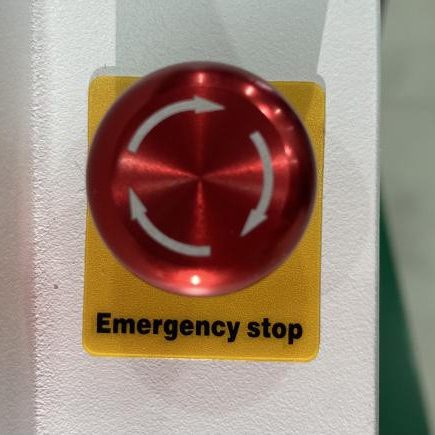

Good Stability: It has the ability to work continuously for a long time, the working performance of the whole machine is stable, and the maintenance cost is low.

Environmental Protection: The heat generated during welding is small, the heat-affected zone is small, the welding quality is high, the welding point is pollution-free, and it meets environmental protection requirements.