1. Background and Inquiry

A valued Turkish client approached us seeking a robust, precise welding solution for their hardware components. They expressed interest in our advanced YAG (Yttrium Aluminum Garnet) laser welding systems, renowned for their versatility in metal-joining applications.

2. Proposed Solution

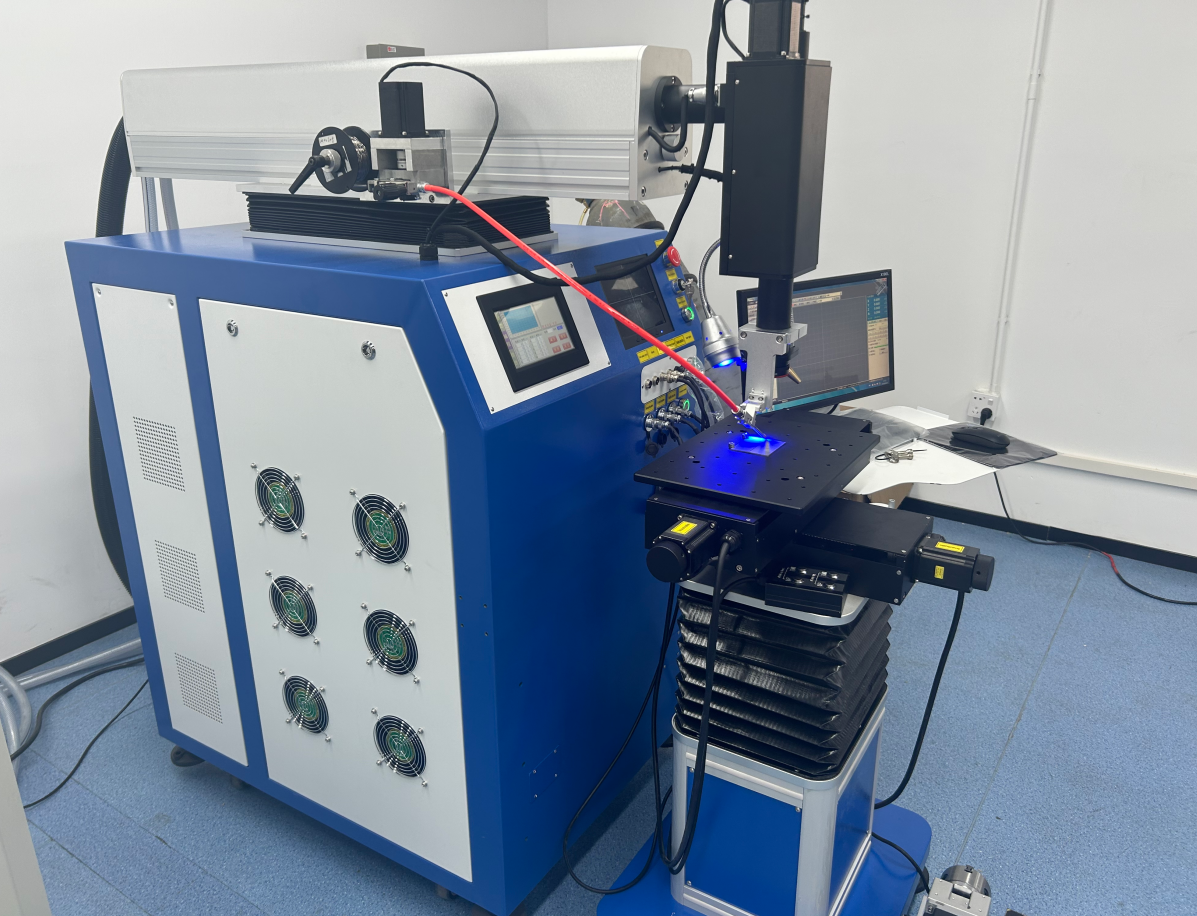

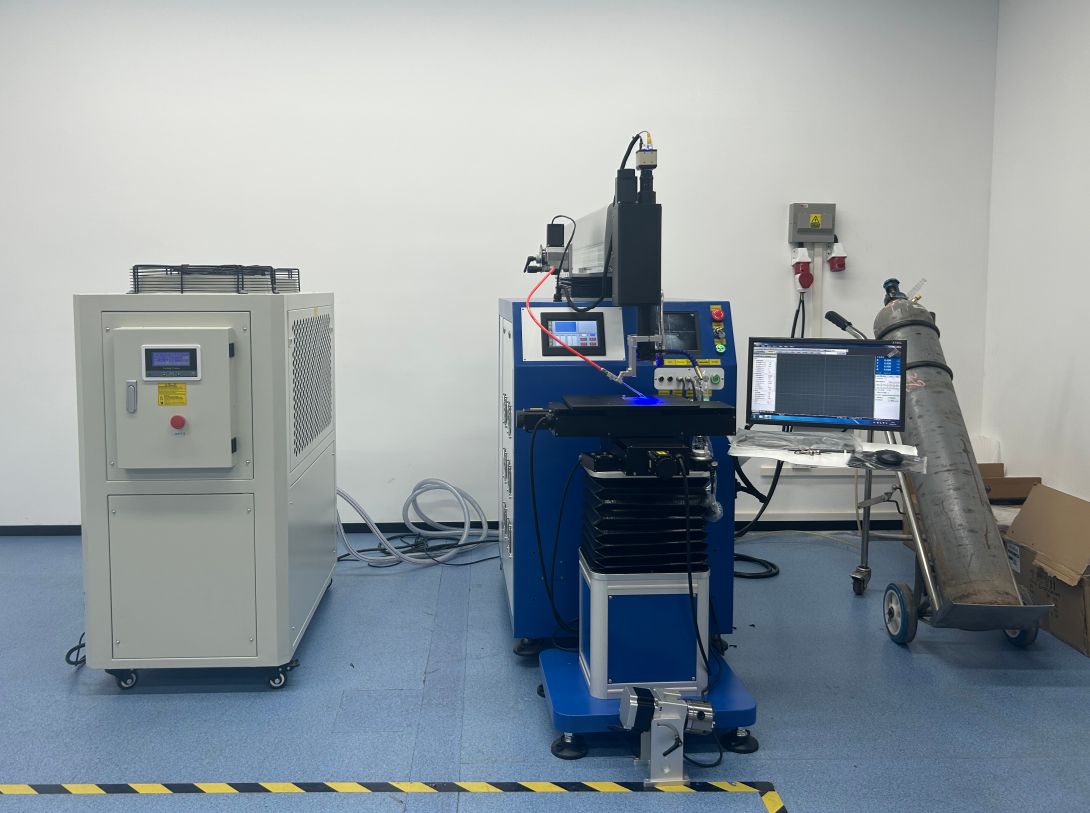

Our technical team carefully analyzed the customer’s requirements and recommended:

-

High-Performance YAG Welding Machine

-

Automatic Wire Feeder

This combination ensures

Consistent addition of filler material

Strong, clean weld seams

Repeatable results on complex geometries

3. Trial Arrangement and Execution

-

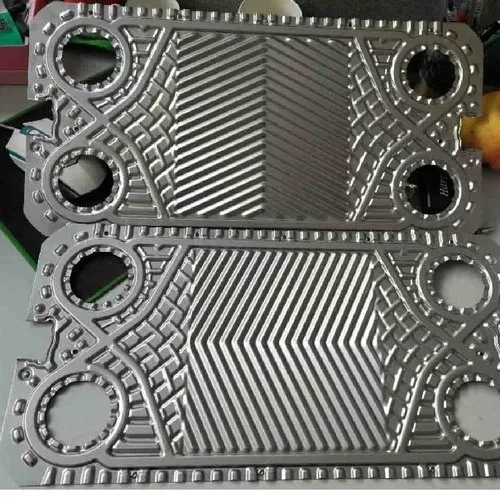

Sample Preparation

-

Customer provided representative hardware fittings and parts.

-

-

Dedicated Welding Test

-

Our YAG system, complete with the automatic wire feed mechanism, was used to weld the samples.

-

-

Key Observations

-

Excellent precision and weld quality

-

High processing speed

-

Flawless, uniform seams thanks to the wire feeder

-

4. Results and Customer Feedback

-

Performance: The system met— and in some aspects exceeded— the client’s stringent production standards.

-

Customer Reaction:

-

Impressed by precision, speed, and overall weld integrity

-

Highlighted the critical role of the automatic wire feeder

-

Praised our team’s professionalism and rapid responsiveness

-

5. Order Confirmation and Next Steps

-

Order Placed: The Turkish manufacturer confirmed their order for the YAG welding machine plus automatic wire feeder and completed payment.

-

Ongoing Support: We are committed to:

-

Smooth installation and commissioning

-

Comprehensive operator training

-

Reliable after-sales service

-

6. Conclusion

This successful collaboration demonstrates the power of combining YAG laser welding technology with automation to handle demanding hardware manufacturing tasks. We look forward to supporting our Turkish client’s ongoing production success with our reliable machinery and dedicated service.

Post time: May-30-2025