What are the advantages of handheld laser welding machine?

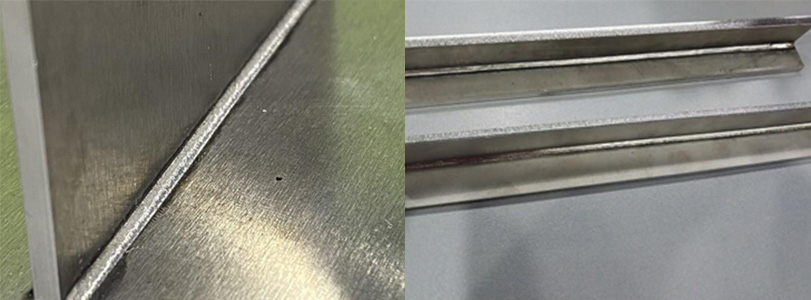

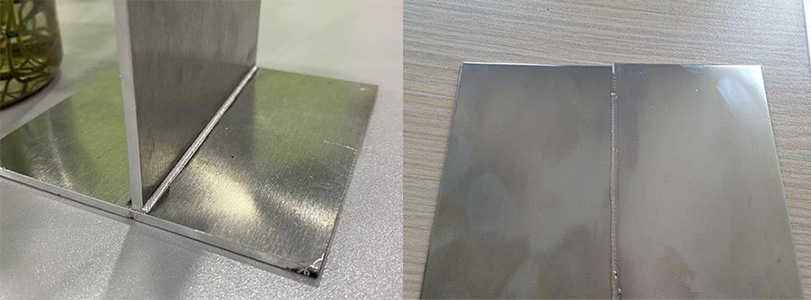

1. The laser beam has high cost performance, faster welding speed, strong and beautiful welding, and provides customers with efficient and perfect welding solutions.

2. Handheld laser welding machine, ergonomic design, flexible and convenient, longer welding distance, can complete welding of product workpieces at any position.

3. The welding area has little heat damage, is not easy to deform, blacken, and has no marks. The welding depth is large, the fusion is sufficient, and it is strong and firm.

4. The photoelectric conversion is efficient, the energy consumption is low, and the operation is simple and easy to understand. No professional welding master is required. Ordinary employees can start work after a short period of training. Long-term use can greatly save production costs.

5. High safety factor, the welding nozzle only works when the power switch is triggered when it touches the metal material, and the triggering power switch contains human body temperature induction.

6. It can complete welding with arbitrary focus, and can weld various complex welding workpieces and large workpieces with non-standard shapes.

7. The new handheld laser cutting equipment adopts a shaking technology system, which has low requirements for welding spacing, can adjust the spot size, improve the light quality, and achieve good welding effect, while the traditional handheld does not have such a function, and the welding speed and quality are far behind the former.

8. The new welding equipment is easy to maintain, low-cost welding, high speed, excellent welding effect, and a wider range of applications, which are not available in traditional handheld laser welding machines

Handheld laser welding head operation and maintenance

1. Handheld laser welding mechanics must undergo their own professional technical training, understand the use of information system indicators and buttons, and be familiar with the most basic equipment management knowledge;

2. The work of the handheld test laser welding machine before processing the slot without damaging the bare wires; the robot body, external shaft, spray gun station, water cooler on non-local items, tools, etc.;

3. It is strictly forbidden to place a liquid object, flammable object and temperature change in the operating room on the control cabinet. The temperature should not exceed 25 degrees Celsius, and there will be no air leakage, water leakage and electricity leakage.

Maintenance of the welding machine

1. Do inspection work regularly.

2. Because the welding machine adopts forced air cooling, it is easy to inhale the surrounding dust and accumulate in the machine. So we can often use clean compressed air to blow away the dust in the welding machine.

3. Regularly check the site wiring of the power cord.

4. In the annual maintenance and inspection, comprehensive technical repair management work such as replacement of some defective parts, repair of the outer shell and reinforcement of the insulation degradation parts should be implemented.

Maintenance of welding torch

1. Regular inspection and replacement of contact tips

2. Periodically organize data cleaning and replacement of spring hoses

3. Inspection of the insulating ferrule

The above-mentioned regular maintenance and inspection can reduce the occurrence of welding failures. Although it takes a certain amount of time and effort, it can extend the life of the welding machine, improve the operating efficiency, ensure the performance of the welding machine, and improve the safety. In addition, in the process of using the handheld laser welding machine, safety protection cannot be ignored.

Post time: Jul-19-2024